Disclosure of the Selected Process of Wastewater Treatment Plant

In biological wastewater treatment, suspended or attached microorganisms can be used. The main purpose is to keep microorganisms in the bioreactor at high concentrations to allow them to use pollutants as a substrate and decrease the pollutant concentrations to acceptable levels. During the treatment the biomass concentration increases due to substrate utilization and the biomass should be separated from the treated water both to have high-quality effluent and also to use the sludge further.

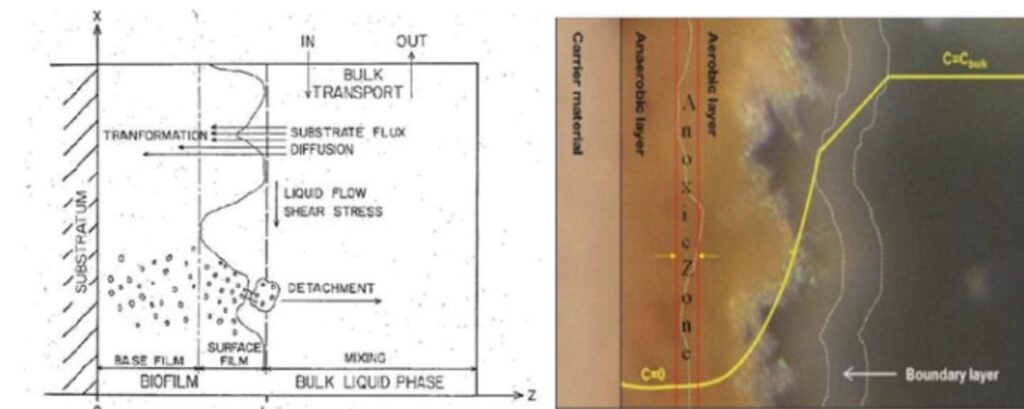

In attach growth processes, microorganisms are kept in the bioreactor by attaching them to solid carrier media. Depending on the carrier media, operational conditions of the bioreactor, and the wastewater characteristics, the biofilm thickness on the media may change between 100 µ and 10 mm. Substrate, oxygen, and nutrients diffuse through the stagnant liquid media and reach the biomass attached to solid media. The by-products originating from the biotransformation are released back into the liquid phase (Metcalf and Eddy, 2014). This transportation is provided in the following Fig. 1.

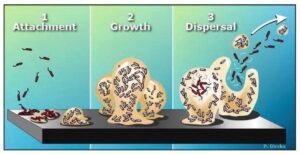

Biomass on the media grows as the substrate is utilized. The growth of biomass does not naturally continue indefinitely, and when it reaches a certain thickness, it detaches and enters the aqueous phase. The biomass released into the water must be removed through sedimentation. However, in place of the detached biomass, new biofilm growth on the carrier begins and the process continues in this cyclic manner as illustrated in the following Fig. 2.

Fig. 1. Substrate transport to the biofilm (Wang et al., 2020)

Fig. 2 The biofilm life cycle on carrier media during wastewater treatment (Wang et al., 2020)

Microorganisms are preferred to live attaching to solid carrier media due to the following advantages (Rittmann and McCarty, 2020);

- Microorganisms in the biofilm may live in a layered structure and they may live on fresh substrate produced by the microorganisms living in the upper layers.

- The biofilm may create a more hospitable environment compared to the liquid phase in terms of pH, O2, and product.

- Different types of microorganisms may live together in biofilm and they provide befits to each other.

- The most important advantage of biofilm for wastewater treatment is the increased biomass concentration within the bioreactor, which lead to decreased volume of the biological tank.

Although biofilm processes have several advantages the most important disadvantage is the high cost of the carrier media. Therefore, the utilization of a hybrid process incorporating both biofilm and suspended growth processes appears to be the most rational option. This way, the advantages of biofilm processes mentioned above can be harnessed, and the investment cost of the process will not be high due to also benefiting also from the suspended biomass.

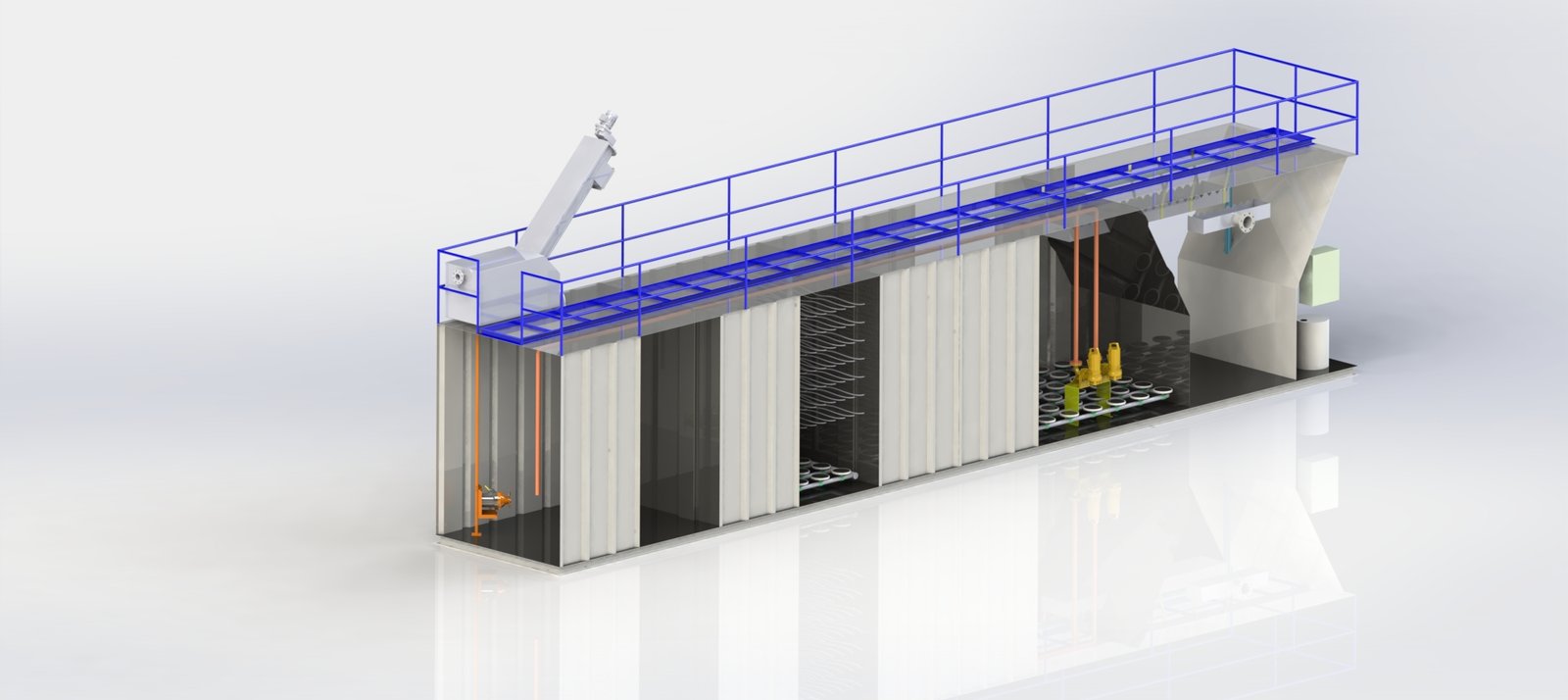

For attached growth, the most commonly used carrier media is the plastic type carries. This type of carrier is used in the activated sludge process and the process is called the integrated fixed film activated sludge (IFAS) (containerized wastewater treatment unit) ( process in which both suspended and fixed film biomass are benefitted. This type of media has a specific gravity of 0.96 to 0.98 g/cm3 and it was originally developed by a Norwegian company (Kaldnes Miljoteknolog) to use the media in moving bed bioreactor process (Metcalf and Eddy, 2014). The original design was around 10-mm diameter, 7-mm in height. However, several different versions have been produced by several different companies. Some examples are provided in the following figure.

Fig. 3 Different types of plastics media used in IFAS or moving bed biofilm reactors (MBBR PACKAGE UNIT)MBBR PAKET ARITMA) kullanılan farklı plastik ortam türleri

The biomass attaches to the media and grows up to a certain thickness as provided in the following Fig. 4.

Fig. 4 Biofilm growth on an attached media. (Ødegaard, H. (2002), Description of the Moving Bed Biofilm Reactor (MBBR- Containerized Wastewater Treatment Unit ))

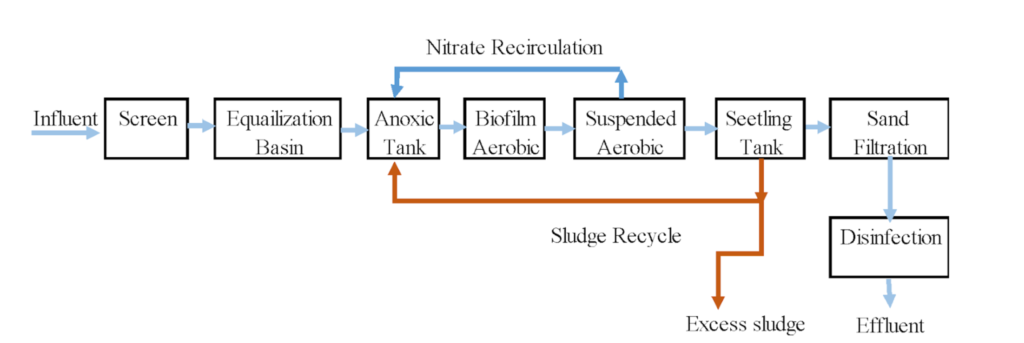

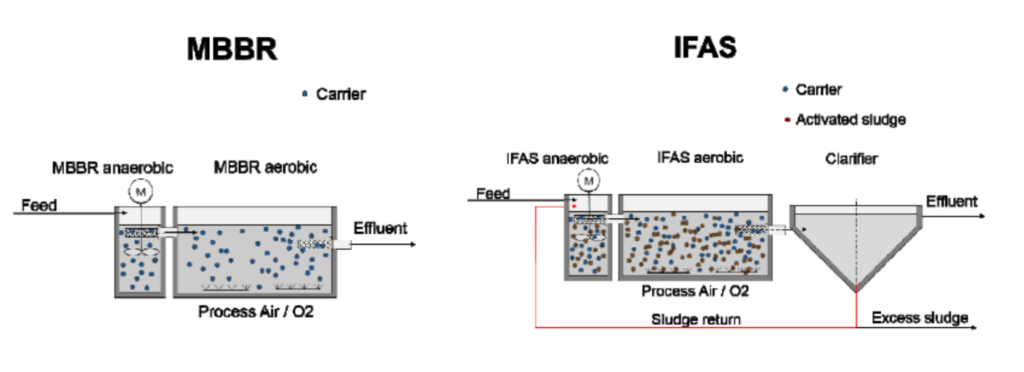

The IFAS and MBBR (containerized wastewater treatment unit) processes are provided in Fig. 8.5. As can be seen from the figure, the main difference between these two processes is that IFAS (containerized wastewater treatment unit) sludge recycle from the settling tank, which allows for the utilization of both suspended and attached biomass.

Fig. 5 Comparison of IFAS and MBBR processes

Hence, in this design, we have selected IFAS (containerized wastewater treatment unit ) as the best process to implement as it provides the use of both suspended and attached growth biomass.

The flow diagram of the selected process is also illustrated in Fig. 6.