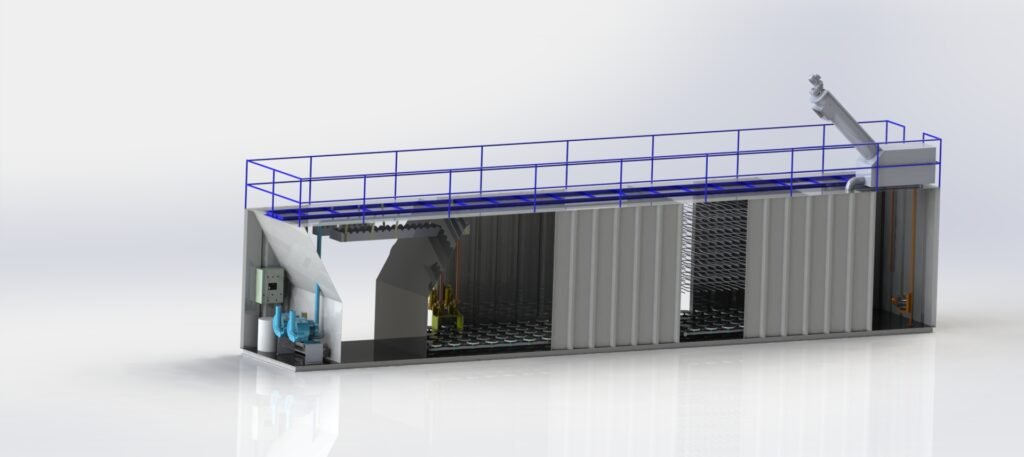

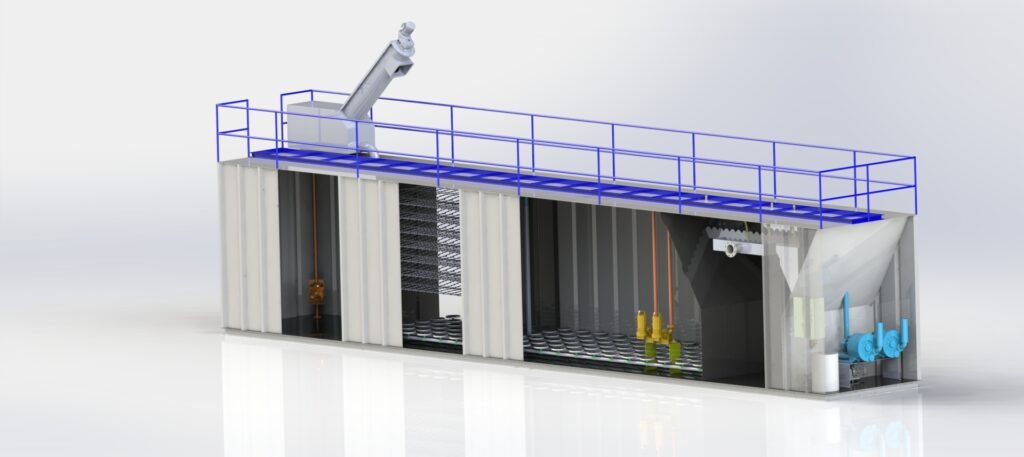

MBBR Package Treatment - Containerized Wastewater Treatment

MBBR MBBR units (Containerized wastewater treatment) are compact treatment units in which activated sludge and biofilm processes are combined with high COD, N, P efficiency. In biological wastewater treatment, microorganisms can be found suspended or attached to the carrier surface. The basic principle in MBBR units is to obtain high quality effluent by keeping the biomass in the rectifier at a high rate. The carrier materials used for the formation of bound biomass have a smaller mass than the wastewater in the reactor and can easily move within the reactor. The most important benefit of the biofilm formed on the carrier material is to provide high microorganism concentration and to realise high treatment efficiency at lower volumes.

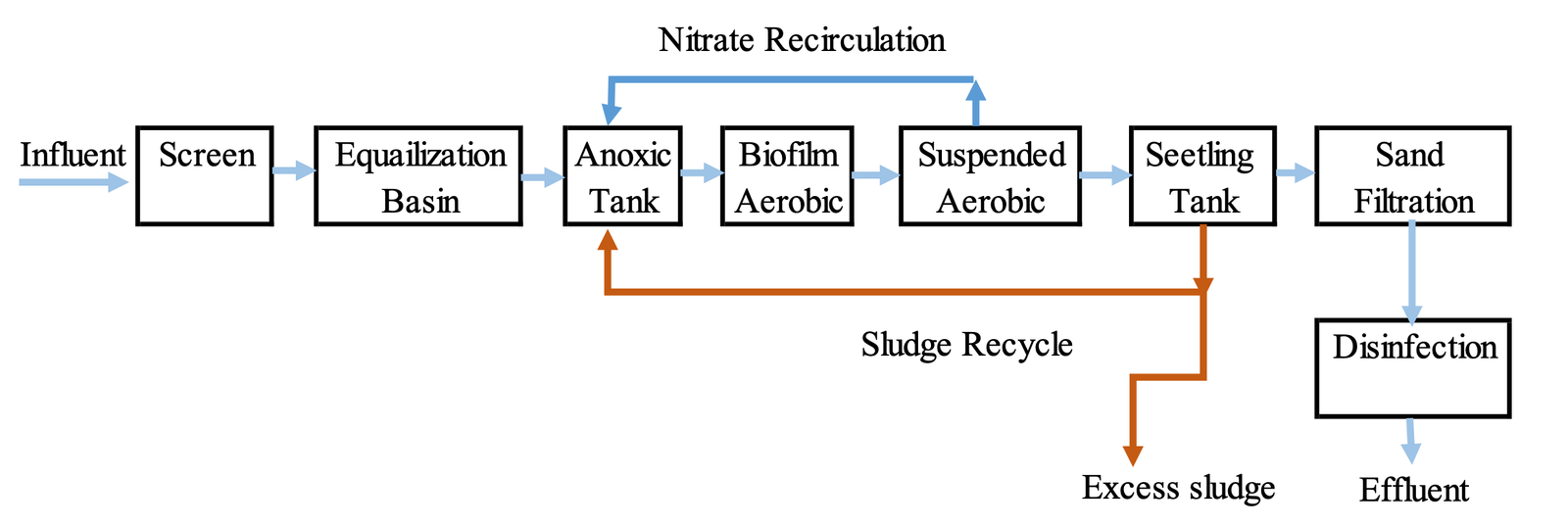

MBBR Üniteleri Proses Akım Şeması

İhtiyaç duyulan deşarj değerleri ve eşdeğer nüfusa göre farklı ölçülerde dizayn edilen MBBR paket arıtma üniteleri St 37 karbon çelikten imal edilip korozyona karşı epoksi boya ile kaplanmaktadır. MBBR üniteleri PLC kontrollü olup tam otomotik olarak çalışmaktadır. Daha sonraki yıllarda nüfusun artış gösterebileceği yerleşim yerleri veya kullanım alanlarında ise birbirinden bağımsız ve paralel çalışan arıtma üniteleri ile uzun yıllar sorunsuz çalışacak sistemler kurulmaktadır

Units forming the MBBR System

Approach Channel

The wastewater to be taken to the MBBR units is first passed through the screen placed in the approach channel and the coarse wastes larger than 20 mm are removed. Depending on the amount of wastewater and the size of the plant, the screen to be used varies manually or automatically.

Preliminary Settling Tank

It is the unit where the non-biodegradable TSS (Total Suspended Solid) in the wastewater is collected and precipitated. Thanks to this process, damage to equipment and equipment such as disc diffuser, submersible pump, moving bed material in the treatment unit is prevented.

Balancing Tank

It is the unit where wastewater is stored before the MBBR units and it is ensured that the wastewater characteristics and flow rate oscillations that may change during the day are minimised. The wastewater is transferred to the MBBR units by the feed pump in the equalisation chamber.

MBBR Containerized wastewater treatment Unit

MBBR units, designed and manufactured by Çevtek Treatment Systems, are systems operating according to the principle of bonded growth process. It has high treatment efficiency and requires a much smaller area requirement compared to conventional treatment systems. The excess sludge generated in the system is subjected to dewatering in sludge drying beds and dewatering systems.

SUPERIORITY OF MBBR UNITS

- Smaller Space Requirement Compared to Conventional Systems

- Providing Solution in Strict Discharge Conditions

- High Purification Technology

- Low Operating Cost Thanks to Fully Automated System

- Completely Closed and Odourless System.

- Durable and Long Lasting

PLACES WHERE MBBR UNITS ARE USED

- In Mines

- Hotel and resort facilities

- In The Construction Field

- Schools and military facilities

- Small settlements such as villages and towns

- Hydro-Electric Power Plants

- Trailer Camps